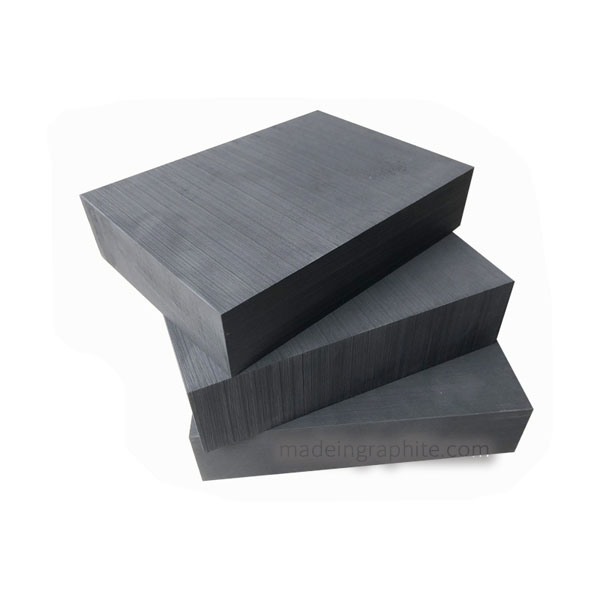

Casting Graphite Block

High Temperature Resistance Casting Graphite Block

High-Temperature Resistant Casting Graphite Blocks are widely utilized in the casting industry. They are suitable not only for the casting of aluminum, copper, magnesium, and other alloys but also for alloy casting applications with high-temperature corrosion resistance requirements. Owing to their excellent thermal conductivity, electrical conductivity, mechanical properties, corrosion resistance, and machinability, casting graphite blocks are finding increasingly extensive use.

Key Advantages of Casting Graphite Blocks

Excellent thermal conductivity: Ensures uniform heating, reducing casting defects.

Strong high-temperature resistance: Maintains stability at extreme temperatures (up to 2000°C in inert environments).

Superior corrosion resistance: Resists molten metals/oxides, extending service life.

High machinability: Easily precision-shaped into complex parts with tight tolerances.

Good electrical conductivity: Fits electromagnetic stirring or electrical heating needs.

Stable mechanical properties: Withstands high-temperature stress and wear.