Graphite Parts for Glass Industry

Custom High Quality Graphite Parts for Glass Industry

In float glass production, four pillars define success: uncompromised quality, pinpoint precision, flawless aesthetics, and maximum purity. Our portfolio of materials and components—designed for large-scale continuous manufacturing—delivers on all fronts, supporting seamless production workflows.

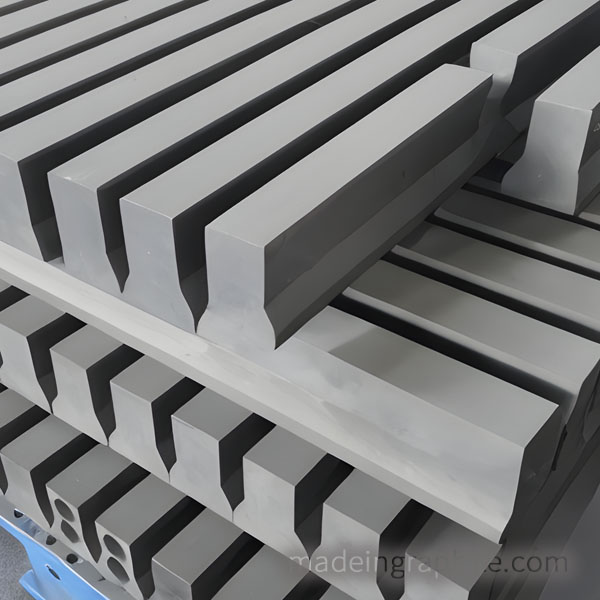

To address the unique demands of float glass machinery, we offer tailor-made graphite parts. A standout application is the graphite dam, a must-have for the tin bath’s 1100°C (2000°F) environment. We prioritize isostatic graphite here, as its exceptional resistance to corrosion and wear ensures reliable performance under harsh conditions.

Beyond performance, our graphite parts drive cost efficiency: their exceptionally long lifespan cuts down on maintenance downtime and lowers overall plant operational costs.